Aston™ LyoSentinel 使用微型質譜優化凍乾工藝瀏覽數: 3636

Aston™ LyoSentinel 使用微型質譜優化凍乾工藝

伯東公司日本 Atonarp Aston™ LyoSentinel 分子傳感質譜儀雙採樣路徑, 滿足冷凍乾燥過程監控, 工具鑒定 (真空完整性), 故障檢測控制的應用.

凍乾或冷凍乾燥是通過昇華將溶劑 (通常是水) 從冷凍溶液中除去, 從而形成可輕易再水化的多孔結構 (餅狀) 的過程. 這種低溫工藝使它成為製藥業等材料的理想選擇. 然而, 工藝過程由於乾燥速率低, 需要真空等操作費用, 導致費用昂貴.

Lyophilization or freeze-drying is the process by which a solvent, typically water, is removed from a frozen solution by sublimation resulting in a porous structure (cake like) that can be easily rehydrated. The low temperature of such a process makes it ideal for materials such as pharmaceuticals. The process is however costly due to, the low drying rate, the use of vacuum, and associated operating expenses.

在控制溫度下的初級乾燥 (昇華) 和二次乾燥 (表面脫附) 迴圈期間, 大量水蒸汽被去除, 以避免不可逆的產品損壞. 由於冷凍乾燥器的託盤和管道受到熱迴圈和機械應力的影響, 可能會發生洩漏, 導致小瓶 (產品) 受到污染. 此外, 用作製冷劑的微量矽油會進入產品腔室, 從而影響產品的無菌性. 另一種類型的矽油也存在於用於密封小瓶的橡膠蓋中. 因此, 在初級和二次乾燥迴圈過程中即時現場監測乾燥效果和工具診斷是至關重要的:

1. 保證“安全”的產品, 因為數千瓶批次在一次運行中被處理(圖1)

2. 冷凍乾燥的投資回報 ROI 更大化.

The bulk of water vapor is removed during primary drying (bulk sublimation) and secondary drying (surface desorption) cycles at controlled temperatures to avoid irreversible product damages. Due to the thermal cycles and mechanical stress the trays and tubing of the freeze-dryer (FD) are subjected to, leaks can develop causing contamination of the vials (product). Furthermore, trace amounts of silicone oil used as a refrigerant can find its way into the product chamber hence compromising the sterility of the product. Another variation of silicone oil is also present in the rubber caps used to seal the vials. Real time in-situ monitoring of the drying efficacy during primary and secondary drying cycles and tool diagnostics are therefore critical to:

1. Guaranteeing “safe” products as batches of thousands of vials are processed in a single run (Figure 1)

2. Maximizing the return on investment (ROI) of FD’s.

質譜是一種無創多通道技術, 能夠提供與上述所有目標相關的測量, 包括:

1. 執行凍乾系統洩漏檢查.

2. 在初級和二級乾燥迴圈結束監測水蒸氣的準確端點檢測

3. 檢測和監測已知和以前未知的污染物的演變

4. 檢測和識別矽油在冷凍乾燥中用作傳熱流體的痕跡

Mass spectrometry is a non-invasive multi-channel technique capable of performing measurements associated with all the tasks described above including:

1. Perform system leak checks.

2. Monitor water vapor for accurate endpoint detection at the end of primary and secondary drying cycles

3. Detect and monitor the evolution of known as well as previously unknown contaminants.

4. Detect and identify traces of silicone oil used as a heat transfer fluid in FDs.

冷凍乾燥工藝控制, 然後調節:

1. 確保良好的產品品質

2. 儘量減少和提高乾燥迴圈的可靠性

3. 增加工具的可用性

4. 通過在空氣洩漏和/或污染物 (如矽油) 發現時中止凍乾迴圈來減少產品報廢

Freeze-drying process control recipes are then concocted to:

1. Ensure good product quality.

2. Minimize and improve the reliability of the drying cycles.

3. Increase tool availability for FD duties.

4. Reduce product scrap by aborting FD cycles at the onset of air leaks and/or contaminants such as silicone oil.

|

Aston™ LyoSentinel 質譜儀過程監控功能和優勢 |

|

• 設計用於凍乾過程監控 Designed for lyophilization process monitoring |

伯東公司代理日本 Atonarp Aston™ LyoSentinel 質譜儀

經過實驗室和生產冷凍乾燥工具的嚴格測試, Atonarp Aston™ LyoSentinel 質譜儀在這類應用中具有更高的優勢. 該質譜包括一個通用核心單元, 配有為凍乾量身定制的前端介面, AMS 核心平臺是一個微型緊湊質譜系統, 具有感測器和相關電子設備, 壓力感測器, 真空歧管和真空泵. 在安裝時, 一個獨立的採樣模組附加到核心平臺上. 該模組包括雙樣品路徑歧管配備加熱器套, 加熱電源和控制器, 和一個可選的樣品泵.

Having gone through rigorous testing on laboratory and production FD tools, Atonarp’s Aston LyoSentinel possesses unparalleled advantages in such applications. The device consists of a generic core unit outfitted with a front-end interface tailored for lyophilization. The AMS core platform is a miniature compact Mass Spec system featuring sensor and associated electronics, a pressure transducer, vacuum manifold, and vacuum pumps. A standalone sampling module is attached to the core platform upon installation. The module includes a dual sample path manifold outfitted with heater jackets, heater supplies and controller, and an optional sample pump.

主路徑具有正在申請專利的膜基篩檢程式, 用於監測乾燥過程和端點檢測. 樣品通過一個管狀膜, 有利於水蒸氣和排斥矽油的滲透率. 第二路徑用於直接進樣, 通過電腦控制的比例閥, 檢測包括矽油在內的污染物的痕跡. 在預設的占空比下自動完成路徑之間的切換. 次秒級的資料更新速率使使用者能夠優化占空比, 從而保護質譜儀室不受矽油積聚和其他污染物的影響, 例如, 停止前給氧.

The primary path features a patent pending membrane-based filter intended for monitoring the drying process and endpoint detection. The sample is drawn through a tubular membrane favoring water vapor and discriminating against silicone oils based on their permeation rates. The secondary path is intended for direct sample injection, through a computer controlled proportional valve, to detect traces of contaminants including silicone oils. Switching between paths is performed automatically under a preset duty cycle. Sub-second data update rates enable the user to optimize the duty cycle and hence protect the Mass Spec chamber from silicone oil build-up and other contaminants, e.g. oxygen prior to stoppering.

在開環控制下操作的比例閥, 被用來維持由壓力感測器測量的質譜儀腔室中的恒定壓力. Aston™ LyoSentinel 質譜儀可以在主從路徑切換時連續工作. 質譜儀可以配置為在不同的電離能, 靈敏度, 解析度和掃描速度設置下掃描不同品質. 薄膜過程中可能出現的感測器和腔室壁.

The proportional valve, operated in open loop control, is utilized to maintain a constant pressure in the Mass Spec chamber as measured by the pressure transducer. The Mass Spec system can operate continuously upon switching between the primary and secondary paths. The Mass Spec can be configured to scan different masses of interest under different ionization energy, sensitivity, resolution, and scan speed settings for each path. sensor and chamber walls that may occur during film.

啟用的質譜儀感測器技術是一個小型陣列的四極品質濾波器並行工作, 以獲得高靈敏度. 該感測器的小尺寸 (< 5 cc) 和在高壓 (mTorr) 下工作的能力使其能夠使用由小型低抽速真空泵抽出的小型真空室 (圖3). 在11 MHz 驅動下, 該感測器覆蓋 100 amu 的品質範圍, 在 2到2 00 ms 的停留時間內具有低到 ppm 以下的靈敏度. 與傳統質譜儀相比伯東 Aston™ LyoSentinel 其他優點包括:

1. 在冷凍乾燥工具上探測戰略位置的能力

2. 以壓力和分數濃度的形式生成定量測量

3. 生成即時自我診斷, 以實現可靠的免維護操作

The enabling Mass Spec sensor technology is a miniature array of quadrupole mass filters operating in parallel for high sensitivity. The sensor’s small size (< 5 cc) and ability to operate at high pressures (mTorr) enable the use of a small vacuum chamber evacuated by small low-capacity vacuum pumps (Figure 3). Driven at 11 MHz, the sensor covers a 100 amu mass range and has low to sub-ppm sensitivity for dwell times ranging from 2 to 200 ms. Other advantages over conventional Mass Spec systems included:

1. The ability to probe strategic locations on the FD tool.

2. Generating quantitative measurements in the form of pressure and fractional concentrations.

3. Generating real time self-diagnostics for reliable maintenance-free operation.

Aston™ LyoSentinel 質譜儀可以實現冷凍乾燥工具鑒定

真空完整性是無菌和工藝性能的關鍵. 四極陣列的高壓能力使 AMS 能夠監測真空泵, 以便早期檢測洩漏和/或污染物. 即時評估真空泵下降曲線的形狀表明工具是否會成功達到其極限真空. 如果發生洩漏, 可以使用氦氣探頭並啟動氦氣洩漏模式來定位這些洩漏. 洩漏檢測通過二次路徑進行, 以實現高速和靈敏度. 作為冷凍乾燥工具的一個組成部分, AMS 依賴於對冷凍乾燥工具進行工藝鑒定.

FD Tool Qualification

Vacuum integrity is key for sterility and process performance. The high-pressure capability of the quadrupole array enables the AMS to monitor the vacuum pump-down for early detection of leaks and/or contaminants. Real time assessment of the shape of pump-down curves indicates whether the tool will successfully reach its ultimate vacuum. In the case of leaks, these can be located using a Helium gas probe and activating the Helium Leak Mode. He leak detection is performed via the secondary path for high speed and sensitivity. As an integral component of the FD tool, the AMS is relied on for qualifying the FD tool for process.

Aston™ LyoSentinel 質譜儀可以實現冷凍乾燥過程監控

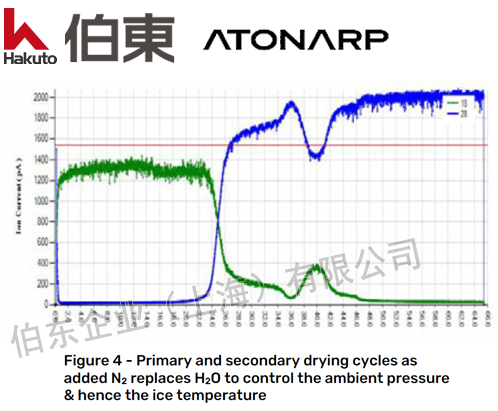

監控乾燥迴圈對於在受控溫度下進行工藝並將這些步驟所需的時間減至更少至關重要. Aston™ LyoSentinel 質譜儀的擴展動態範圍 (長達 60年) 能夠準確可靠地檢測一次乾燥迴圈的終點, 超過該終點, 二次乾燥開始. 圖4 顯示了一次乾燥和二次乾燥期間選擇離子監測模式 (SIM) 時的典型水蒸氣和氮趨勢. 為了進行可靠的端點檢測, 電離能降低到 43 eV,因此消除了 m/z 36 雙電荷氬同位素對 m/z 18 濕度測量的干擾.

FD Process Monitoring & Control

Monitoring the drying cycles is critical to carrying out the process at controlled temperatures and minimizing the time required by these steps. The extended dynamic range (up to six decades) of the Aston LyoSentinel enables accurate and reliable detection of the endpoint of the primary drying cycle, beyond which secondary drying starts. Figure 4 shows typical water vapor and nitrogen trends in select ion monitoring mode (SIM) during primary and secondary drying. For reliable endpoint detection, the ionization energy is lowered to 43 eV, hence eliminating

interferences with moisture measurements at m/z 18 from doubly charged argon isotopes at m/z 36.

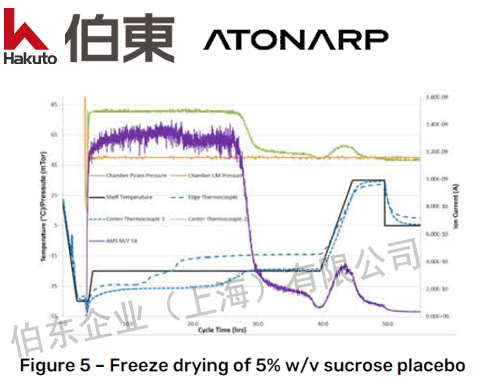

與其他感測器 (如皮拉尼壓力計) 相比, Mass Spec 的一個主要優點是能夠測量監測二次乾燥階段終點所需的低得多的水蒸汽濃度. 圖5 顯示了皮拉尼壓力計無法跟蹤乾燥過程, 包括在低於 50°C/mTorr 的一次迴圈的大部分時間內.

A major advantage of Mass Spec over other sensors, such as Pirani gauges, is the ability to measure much lower water vapor concentrations needed to monitor the endpoint of the secondary drying phase. Figure 5 shows the inability of the Pirani gauge to follow the drying process, including during a significant portion of the primary cycle below 50 °C/mTorr.

AMS 在量化水分濃度, 檢測二次乾燥階段的終點以及確定其他觀察特徵的形狀和時間方面的性能經驗證與 Karl Fisher 滴定金標準和近紅外光譜法一致.

The performance of the AMS in quantifying the moisture concentrations, detecting the endpoint of the secondary drying phase, and determining the shape and timing of other observed features were verified to be in good agreement with the Karl Fisher titration gold standard and NIR spectroscopy.

Aston™ LyoSentinel 質譜儀可以鑒定故障檢測控制

矽油 (聚二甲基矽氧烷) 用作傳熱流體, 用於凍乾內樣品架的溫度控制. 這種化合物在冷凍乾燥條件下 (低壓, 中等溫度) 會揮發. 必須在工藝過程的早期檢測腔室中的油蒸汽痕跡 (ppm 水準), 以避免不可逆轉的污染和整個產品批次的浪費.

Fault Detection Control

Silicone oil (polydimethylsiloxane) is used as a heat transfer fluid for temperature control of shelves inside the FD. Such a compound gets volatilized at freeze drying conditions (lowpressure, moderate temperature). It is imperative to detect traces (ppm levels) of oil vapors in the chamber early during the process to avoid irreversible contamination and the waste of entire product batches.

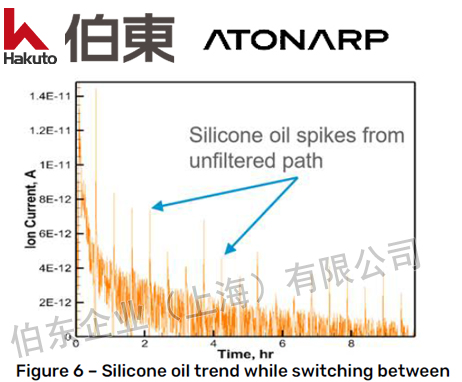

Aston LyoSentinel 質譜儀引入的新方法是以較低的頻率監測矽油的特徵峰, 與通過篩檢程式的乾燥過程相比. 圖6 顯示了放置在空凍乾工具內的培養皿中的監測趨勢. 在任意 10:1 占空比的採樣路徑之間切換時採集資料. 峰值對應於通過次級未過濾路徑的機油信號. 還可以監測與小瓶橡膠蓋中的油有關的其他特徵峰. m/z 73 時矽油特徵峰的最大值. 出於驗證目的, 0.8 mg 油.

The novel method introduced with the Aston LyoSentinel is to monitor the signature peaks for silicone oils at a lower frequency compared to that of the drying process via the filter. Figure 6 shows a monitoring trend deposited in a petri dish was placed inside an empty FD tool. The data is collected while switching between sampling paths with an arbitrary 10:1 duty cycle. The spikes correspond to oil signals through the secondary unfiltered path. Other signature peaks associated with oil from the rubber caps of the vials can also be monitored. of the silicone oil signature peak at m/z 73. For validation purposes, 0.8 mg of oil.

Aston LyoSentinel 質譜儀的雙採樣路徑具有以下優點:

1. 使用高採樣頻率的過濾主路徑, 密切監測乾燥過程

2. 使用過濾路徑保護質譜腔室和感測器不受油蒸汽累積的影響, 從而延長設備的壽命和可靠性

3. 使用較低採樣頻率的二次路徑檢測污染

4. 由於較長的停留時間可用於監測有限數量的特徵峰, 因此使用二次路徑實現對油和其他污染物的高靈敏度檢測(subpm)

5. 匯出洩漏尺寸的定量測量值, 作為凍乾工具用戶的閾值指示器

The Dual sampling path of the Aston LyoSentinel offers several advantages including:

1. Using the filtered primary path at a high sampling frequency to closely monitor the drying process.

2. Using the filtered path to protect the MS chamber and sensor from the accumulation of oil vapors over time and hence extend the lifetime and reliability of the device.

3. Using the secondary path at a lower sampling frequency to detect contamination.

4. Using the secondary path to enable high sensitivity (subppm) for the detection of oil and other contaminants as

longer dwell times can be used to monitor a limited number of signature peaks.

5. Deriving quantitative measurements of the size of the leaks as threshold indicators to FD tool user.

若您需要進一步的瞭解 Atonarp Aston™ LyoSentinel 質譜儀詳細資訊或討論, 請參考以下聯絡方式:

上海伯東: 葉小姐 臺灣伯東: 王小姐

T: +86-21-5046-3511 ext 107 T: +886-3-567-9508 ext 161

F: +86-21-5046-1490 F: +886-3-567-0049

M: +86 1391-883-7267 ( 微信同號 ) M: +886-975-571-910

qq: 2821409400

現部分品牌誠招合作代理商, 有意向者歡迎聯絡伯東 王小姐 +886-975-571-910

伯東版權所有, 翻拷必究

![]() +886-2-8772-8910

+886-2-8772-8910