Aston™ 在線質譜分析儀應用於 EUV 極紫外光源鹵化錫原位定量瀏覽數: 1026

伯東公司日本 Atonarp Aston™ 在線質譜儀應用於半導體光刻技術 EUV 極紫外光源鹵化錫原位定量

EUV 極紫外光刻技術越來越多地用於支援 <10nm 工藝技術的關鍵尺寸圖案形成. 管理這些價值超過 2億美元光刻機的正常執行時間和生產量對晶圓 Fab 廠的經濟至關重要. 伯東公司日本 Atonarp Aston™ 在线質譜分析儀通過快速, 可操作, 高靈敏度的分子診斷數據實現了最佳的反射板鍍錫層清潔, 並且 Aston™ 質譜仪的即時氫氣 H2 監測也降低了每個 EUV 工具的氫氣消耗.

EUV lithography is increasingly being deployed to support critical dimension patterning for <10nm process technologies. Managing up-time and throughput of these >$200M lithography tools is critically important to FAB economics. Aston from Atonarp enables optimal reflector plate tin deposit cleaning with fast, actionable, high-sensitivity molecular diagnostic data and Aston’s real time H2 monitoring also reduces the hydrogen consumption per EUV tool.

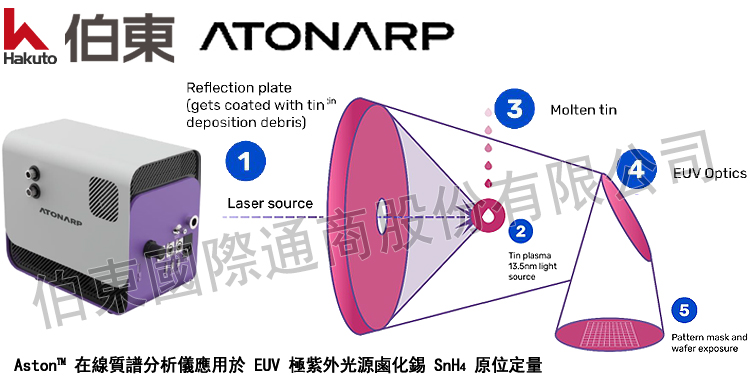

隨著工藝幾何尺寸的不斷縮小, 半導體工藝製造商面臨著新的挑戰. 在先進的極紫外 EUV 光刻技術中, 13.5nm 波長的光源是通過二氧化碳 CO2 雷射器蒸發熔融錫 Sn 液滴, 從而產生等離子體. 大批量生產的關鍵挑戰包括控制蒸發錫再沉積引起的光學污染所造成的缺陷.

As process geometries continue to shrink, a new challenge for semiconductor process manufactures has emerged. In advanced Extreme UltraViolet (EUV) lithography, a 13.5 nm wavelength light source is created by vaporizing droplets of molten Tin (Sn) with a carbon dioxide CO2 laser, creating a plasma. The key challenges in high volume manufacturing include controlling defect levels caused by optics contamination from vaporized Tin re-deposits.

光源產生的一個副產品是 EUV 光源反射光學元件上的錫 Sn 碎片, 該反射光學元件聚焦等離子體發出的 EUV 光. 收集鏡塗層表面上的錫沉積導致 EUV 鏡的反射率降低. 沉積錫厚度約為 1nm(只有幾個原子層)會使收集鏡反射率降低多達10%, 通常被視為收集鏡壽命規範. 這種污染增加了提供足夠的 EUV 功率以形成晶圓所需的時間, 因此降低了光刻產量, 並可能影響光刻圖案的定義. 解決措施包括使用氫等離子體 (結合磁場) 以錫烷氣體 SnH4 的形式化學去除錫, 然後從真空室有效排氣, 並防止錫進一步再沉積.

A by-product of the light source creation is tin (Sn) debris on the EUV light source reflective optics, which focuses the EUV light emitting from the plasma. Tin deposition on the coating surface of the collector mirror results in a reduction in the reflectivity of the EUV mirror. A deposited tin thickness of around 1 nm, (only several atomic layers) reduces the collector mirror reflectivity by as much as 10%, commonly regarded as the collector mirror lifetime specification. Such a contamination increases the time needed to deliver enough EUV power to pattern a wafer and therefore reduces lithography throughput and can compromise lithography pattern definition. The mitigation measures include using hydrogen plasma (combined with a magnetic field) to chemically remove tin in the form of stannane gas (SnH4), then efficiently exhaust from the vacuum chamber, and prevent any further tin redeposition.

伯東公司 Aston™ 在線質譜分析儀 EUV 極紫外光源鹵化錫原位定量解決方案

在反射板清潔期間, 需要實現現場測量, 快速, 準確地測量錫 SnH4 端點, 確保以最省時的方式清除錫沉積物, 通過使用 Aston™ 質譜儀可以測量 H2 大氣中 0.01-1 ppm 濃度下的微量 SnH4. 此外, Aston™ 還可以監測 EUV 工具前端的氣體成分.

Fast, accurate measurement of stannane (SnH4) endpoint, using in-situ measurement during the reflection plate clean, ensures that tin deposits are cleared in the most time-efficient manner. Deployed on tool, Aston can measure SnH4 at 0.01-1 ppm trace concentrations in H2 atmosphere. Additionally, Aston can monitor the gas composition in the fore line of the EUV tool.

Aston™ 質譜儀價值在於通過監測從 EUV 腔室中抽空所有錫原子的效率和優化氫氣 H2 流量, 實現有效的終點檢測. 通過最大限度減少氣體流量, 可以降低每分鐘 100 標準升的高純度氫氣消耗量.

Aston’s value is in effective end point detection via monitoring the efficiency of evacuating all tin atoms from the EUV chamber and optimizing the flow of hydrogen (H2). By minimizing gas flow the high purity H2 consumption of 100s of standard liters per minute, can be reduced.

伯東公司代理日本 Atonarp 高科技分子傳感和數位診斷測試設備. Atonarp 通過結合先進的電子和數字處理演算法, 開創了化學成分分析領域的先河. 使高效, 經濟, 即時的獲取分子資訊成為現實! Atonarp 提供適用於半導體過程監控的 Aston™, 以及用於製藥業的 LyoSentinel™ / AMS 1000 和新平臺技術 ATON-360 ( 無需使用化學試劑即可提供實驗室品質的結果. 實現即時, 非侵入數位分子診斷測試.). Atonarp 是製藥, 半導體製造, 工業過程控制以及生命科學領域的分子診斷數字轉換的先驅.

若您需要進一步的瞭解 Atonarp Aston™ 在線質譜儀詳細資訊或討論, 請參考以下聯絡方式:

上海伯東: 葉小姐 臺灣伯東: 王小姐

T: +86-21-5046-3511 ext 107 T: +886-3-567-9508 ext 161

F: +86-21-5046-1490 F: +886-3-567-0049

M: +86 1391-883-7267 ( 微信同號 ) M: +886-975-571-910

qq: 2821409400

現部分品牌誠招合作代理商, 有意向者歡迎聯絡伯東 王小姐 +886-975-571-910

伯東版權所有, 翻拷必究

![]() +886-2-8772-8910

+886-2-8772-8910